Speak to an Air Purification Expert

Speak to an Air Purification Expert

Local Exhaust Ventilation Systems

Protect your workforce and maintain cleaner operations with local exhaust ventilation. Air Quality Engineering, Inc. designs source capture arms and local exhaust ventilation systems that remove harmful airborne contaminants such as welding smoke, coolant mist, and grinding dust right at the source. Built on years of engineering development and customer feedback, AQE systems give you reliable contaminant control while keeping your shop safe, productive, and compliant.

Products

AQE2000 Media Air Cleaner for Welding Fume Extraction & Other Industrial Applications

Portable cartridge unit with a compressed air cleaning system.

View DetailsPorta Air™ Portable Industrial Air Cleaner

Portable cartridge unit without the compressed air cleaning system. Compare to AQE2000 but without pulse system.

View DetailsAQE4000 Jet Dust Collector

Overhead cartridge system compressed air cleaning system, suitable for large quantities of dry dust.

View DetailsM32V Industrial Air Filters

Small industrial portable source capture system. Ideal for small welding applications.

View DetailsM66V Media Air Filtration Systems

Large portable industrial source capture system. Largest of the media, portable units we have to offer.

View DetailsF33V Air Filtration System

Portable, small industrial electrostatic unit. Suitable for source capture.

View DetailsM33V Air Filtration System

Small industrial portable source capture system. Slightly taller than M32V to accommodate longer bag filters.

View DetailsHEPA Filter Air Cleaners: Portable M68V Air Purifiers

Portable industrial HEPA air cleaner. This air cleaner is intended only for source capture.

View Details

Create a Clean Work Environment With Local Exhaust Ventilation

Innovative Design

Parallel linkage source capture arms provide maximum stability and airflow, eliminating spring-back and keeping position with one hand.

Capture pollutants at the source

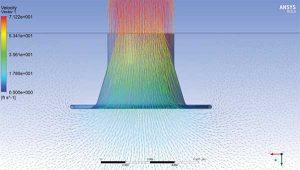

Conical hood design maximizes capture velocity further from the hood, pulling contaminants directly from the breathing zone before they spread.

Maximize efficiency

Smooth interiors and CFD-engineered hoods reduce airflow restrictions, ensuring effective contaminant capture.

Fit any application

From portable units to overhead dust collectors, AQE systems adapt to welding, grinding, mist collection, and other industrial needs.

Simplified operation

Optional LED hoods, blower controls, and dampers make systems easy to use across single or multi-arm installations.

Created for durability

Minimal wear components extend service life and reduce maintenance costs.

Partner with AQE

With decades of industry expertise, Air Quality Engineering is the trusted partner for manufacturers, welders, and fabrication shops nationwide. Our local exhaust ventilation systems are designed to protect workers, reduce compliance risks, and keep operations efficient. Partner with AQE for reliable performance, responsive support, and proven results.

Frequently Asked Questions

What is local exhaust ventilation, and how does it work?

Local exhaust ventilation (LEV) systems capture contaminants directly at the source — such as welding arcs, grinding wheels, or mist-producing equipment — before they disperse into the workplace. By removing harmful particles and fumes immediately, LEV protects worker health and keeps facilities compliant with OSHA and industry standards.

Which local exhaust ventilation system is right for my facility?

The best system depends on your process and space. Portable units like the Porta Air™ or M32V work well for flexible setups or smaller welding stations. Ambient units such as the M66V reduce overall airborne dust and fumes in larger shops. Overhead systems like the AQE4000 are ideal for heavy-duty applications where direct source capture and long service intervals are critical.

Do AQE source capture arms make a difference compared to traditional designs?

Yes. AQE’s parallel linkage arms solve the biggest problem with older designs: spring-back and instability. They are easy to move with one hand, hold their position when extended, and maximize airflow with minimal restrictions. Optional features such as LED lights, dampers, and hood-mounted blower controls make them even more efficient and user-friendly.

What makes AQE’s hood design more effective?

Our source capture arms use a conical hood engineered with computational fluid dynamics (CFD) modeling. This design maximizes capture velocity further from the hood, allowing more forgiveness in positioning. The result is higher efficiency, less user error, and more consistent contaminant removal across different applications.