Speak to an Air Purification Expert

Speak to an Air Purification Expert

MERV Rating

August 6th, 2018 | Posted in Air Cleaners

One common term used when discussing air filtration is the MERV rating. Take a moment to understand what MERV ratings are, and how they applied to your application. Before delving in, it helps to know that MERV is an acronym for Minimum Efficiency Reporting Value, and it is a standard scale used to rate the effectiveness of air filters in terms of filtering particulate from the air.

MERV Scale

The American Society of Heating, Refrigeration and Air-Conditioning Engineers, also known as ASHRAE, created the MERV scale. The MERV scale goes from 1 to 20, where the higher the number, the more effective it is at removing the smallest particulates. Filters with ratings above 16 are classified as HEPA, commonly referred to as High Efficiency Particulate Arrestance.

It should be noted that there have been revisions to the standard since its first inception in 1987. In the original standard 52.1, there were three major measurements used to evaluate filters. These were Arrestance, Atmospheric Dust Spot Efficiency, and Dust-Holding Capacity.

- Arrestance, defined as the ability of a filter to remove synthetic dust, was used to determine the efficiency of low MERV filters.

- Atmospheric Dust Spot Efficiency, defined as the ability of a filter to remove atmospheric dust from the air, was used for higher MERV filters.

- Dust-Holding Capacity is the measure of the amount of dust that a filter could hold.

The issue with the original 52.1 standard was it did not account for the efficiency of the filter with specific particle sizes.

The revised standard, 52.2 helps with determining the efficiency of the filter by taking the size of the particulate into account. The atmospheric dust spot efficiency is no longer used in 52.2 because the analyzing of filter efficiency in removing specific sizes of particulate took its place. Arrestance and dust-holding capacity are still used for MERV 1 to 4 filters. Additional information on MERV ratings can be found at the National Air Filtration Association website: https://www.nafahq.org/understanding-merv/.

Applying MERV

The next thing to consider is how the MERV values relate to removing different size particulates. In the table below under the heading, Composite Average Particle Size Efficiency, there are three columns showing different ranges of particle size. The corresponding rows are divided into four groups based on the MERV rating.

Looking at the chart, one may be inclined to simply use a MERV 16 filter only, as it will capture 95% or more of everything. In theory that is true, but one needs to look at other factors such as cost of the filter and dust holding capacity. Generally, the more efficient the filter is, the more expensive it is. In addition, it will typically have a smaller dust-holding capacity.

MERV and Particle Removal Efficiency

Several factors are considered when determining which filter to use for an application, for there are usually several options that will suffice. First, one needs to determine what contaminant needs to be filtered. The contaminant to be filtered could be as large as lint particles or as small as talcum dust – or could encompass a wide range of particle sizes.

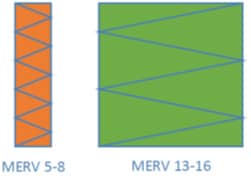

For the majority of the applications we encounter, we typically use a low MERV filter (such as a MERV 8), often referred to as a prefilter, followed by a higher MERV main filter (such as a MERV 14). The reason for using a low MERV filter before a high MERV filter is to manage cost. Low-MERV filters are relatively inexpensive and can capture much of the contaminant before it reaches the main filter, thus extending the life of the more expensive main filter.

When the application has a significant amount of larger particulate, we will recommend adding an even lower prefilter to the mentioned configuration, which would result in three layers of filtration. Again this goes back to extending overall filter life and reducing cost.

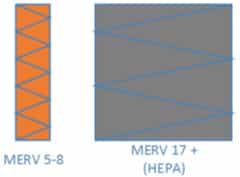

On the other extreme, if one has a large amount of smaller particulate or a very hazardous contaminates, we will recommend adding a HEPA filter after the MERV 14 filter in order to further polish the air off. If the amount of small particulate is very low, then one could go with just a MERV 11 prefilter and a HEPA filter. One typically does not put a high MERV filter before a low MERV filter because the majority of the particulate would be filtered out by the expensive filter, and not the cheaper filter.

LOWER MERV FILTERS ARE TYPICALLY PLACED BEFORE HIGHER MERV FILTERS

TYPICAL CONFIGURATION FOR A LOT OF APPLICATIONS

CONFIGURATION FOR APPLICATIONS WITH A LOT OF LARGE PARTICULATES

CONFIGURATION FOR APPLICATIONS THAT HAVE SMALL PARTICULATE THAT REQUIRE HEPA

CONFIGURATION FOR APPLICATIONS WITH A LOT OF SMALL PARTICULATE THAT REQUIRE HEPA

Basically, the name of the game when it comes to picking filters is striking a balance between making sure the contaminant is collected, maximizing filter life, and managing the costs associated with filter replacement. If filter replacement cost is an issue, keep in mind that Air Quality Engineering, Inc. carries a line of electrostatic air cleaners that have washable filters that may prove to be a more cost-effective option.