Speak to an Air Purification Expert

Speak to an Air Purification Expert

How To Maintain Your Industrial Air Cleaner

January 4th, 2022 | Posted in Air Cleaners

In many environments, industrial air cleaners are a must for businesses. These systems are highly useful in workplaces and settings that produce a lot of dust, oil mists, or other particulate matter. Having a good industrial air cleaning system means protecting your employees’ health, your workplace, and increasing overall productivity.

And as you know, these systems are a long-term investment. And how can you make that investment last even longer, while working as efficiently and effectively as possible? Properly maintaining your industrial air cleaner will go a long way for you and the machine. Our must-haves for a proper maintenance plan are listed below. Incorporate them into your workplace to see more success and longer equipment life!

Have The Correct Air Filtration System For Your Needs

One of the key aspects of making sure your industrial air cleaner runs effectively and efficiently is to make sure that you have the correct one. Different industries require different air cleaners, with different strengths and purposes. Air Quality Engineering, Inc. offers a sizing calculator here to help you start your research. To determine specifically what you need for your business, it is best to consult with one of our expert technicians. This will save you time, energy, and lots of money down the road.

To figure out the correct industrial air filtration system size:

- Determine the air exchange rate, or the AER, for your industry.

- Calculate the total cubic feet of your work area (the area that requires air filtration).

- (Length of work area) x (Height of work area) x (Width of work area)

- Divide the total cubic feet of the work area by your AER to determine the size you need.

While the size of the machine and your space is important, there are other aspects to consider when choosing an industrial air cleaner system. This can include the maintenance and service of the system, intended use for the machine, and your industry. By considering all these factors, you’re more likely to utilize the machine that works the best for your business- and your wallet.

Regularly Clean & Inspect Industrial Air Cleaners

To maintain your industrial air cleaner and extend its equipment lifespan, it is crucial to regularly clean it. Read through the owner’s manual for exact instructions on cleaning, or contact your manufacturer. Cleaning the machine correctly will help prevent rust, leaks, or other degradation. It can also help you keep the air in your workplace as clean as possible, for longer periods.

Regular inspections of your industrial air cleaner also help extend the life of the machine. Inspections should be done by a professional, someone from the manufacturing company, or an expert in your company. They will check for things like:

- Overall status and appearance of the machine

- Regulator pressure (for units with reverse pulse cleaning)

- Leaks in the system where air escapes

- Fan vibration readings

- Cleaning cells

- Replace broken ionizer wires

- Wiping down build up of coolants

- Monitor pressure drop across filters to determine when to replace them

- Inspect belt tension

- Inspect gaskets and seals to ensure air doesn’t leak

By doing these inspections, you ensure that your industrial air cleaner is clean, up-to-date, and performing without any major problems.

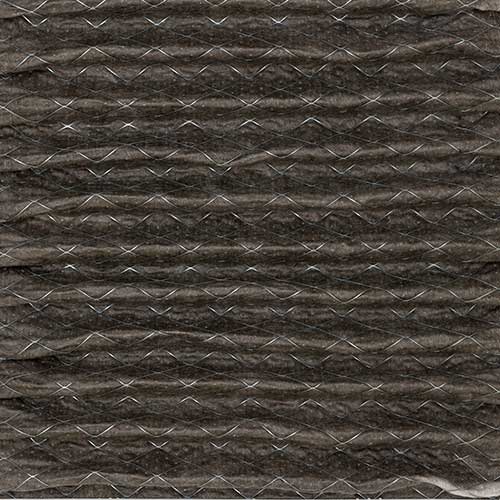

Use Correct Replacement Parts, Especially Filters

Should you need to replace a part or service a component of the machine, ensure that you are using the manufacturer’s equipment or recommended parts. In this case, filters are the most common part to be replaced over time. Make sure you are using the correct size and efficiency level, so your machine can continue to operate at its highest efficiency. And it’s not just filters you need to keep an eye on. There are other consumables like carbon filters, ionizing wires and cell cleaner. This will also help you keep costs down over time, decrease the need for more repairs/maintenance, and remove the worry that your filter is not functioning properly.

Ensure Employees Know How to Use System

Whomever you choose to clean your industrial air cleaner or inspect it, make sure they are knowledgeable about the said machine. Educate yourself and your employees on how to clean the machine, signs of a problem, when to replace the filter, and more. It will help protect you from unnecessary problems in the future.

By following our maintenance plan recommendations, you can prolong the life of your industrial air cleaner, while improving your workplace environment. Not sure where to get started, or need help with maintenance? Air Quality Engineering has over 30 years of experience in the business, and we’re here to help you. Contact us today about your air quality needs!